Quality Services

With decades of industry experience, we specialize in providing top-tier industrial materials and equipment that empower businesses to reach new heights of efficiency and innovation. Our commitment to quality and precision ensures that our clients receive unparalleled support and solutions tailored to their specific needs.

Facility Capabilities

Qty (12) 25’ Open Furnaces

Max temp: 2300°F (12)

Max weight: 20,000 lbs.

Max size: 40”H x 68”W x 25’L

Qty (1) 15’ Open Furnace

Max Temp: 1900°F

Max weight: 20,000 lbs.

Max Size: 40”H x 80”W x 15’L

Qty (2) 8’ Endothermic Atmosphere

Max temp: 1400-1900°F

Max weight: 4,000 lbs.

Max size: 30”H x 46”W x 8’L

Qty (27) 8’ Open Furnaces

Max Temp: 2300°F

Max weight: 4,000 lbs.

Max size: 30”H x 46”W x 8’L

The Standard Since 1973

Services Breakdown

Normalizing

Treatment consisting of heating uniformly to temperature at least 100°F above the critical range and cooling in still air at room temperature. This treatment produces a recrystallization and refinement of the grain structure and gives uniformity in hardness and structure to the material.

Click Below for Video Samples

Hardening (Austenitizing)

Hardening is done by heating uniformly to a temperature above the critical range and rapidly cooling by quenching.

Atmosphere Heat Treating

Used to prevent scale formation (from decarburization) on the surface of parts when needed

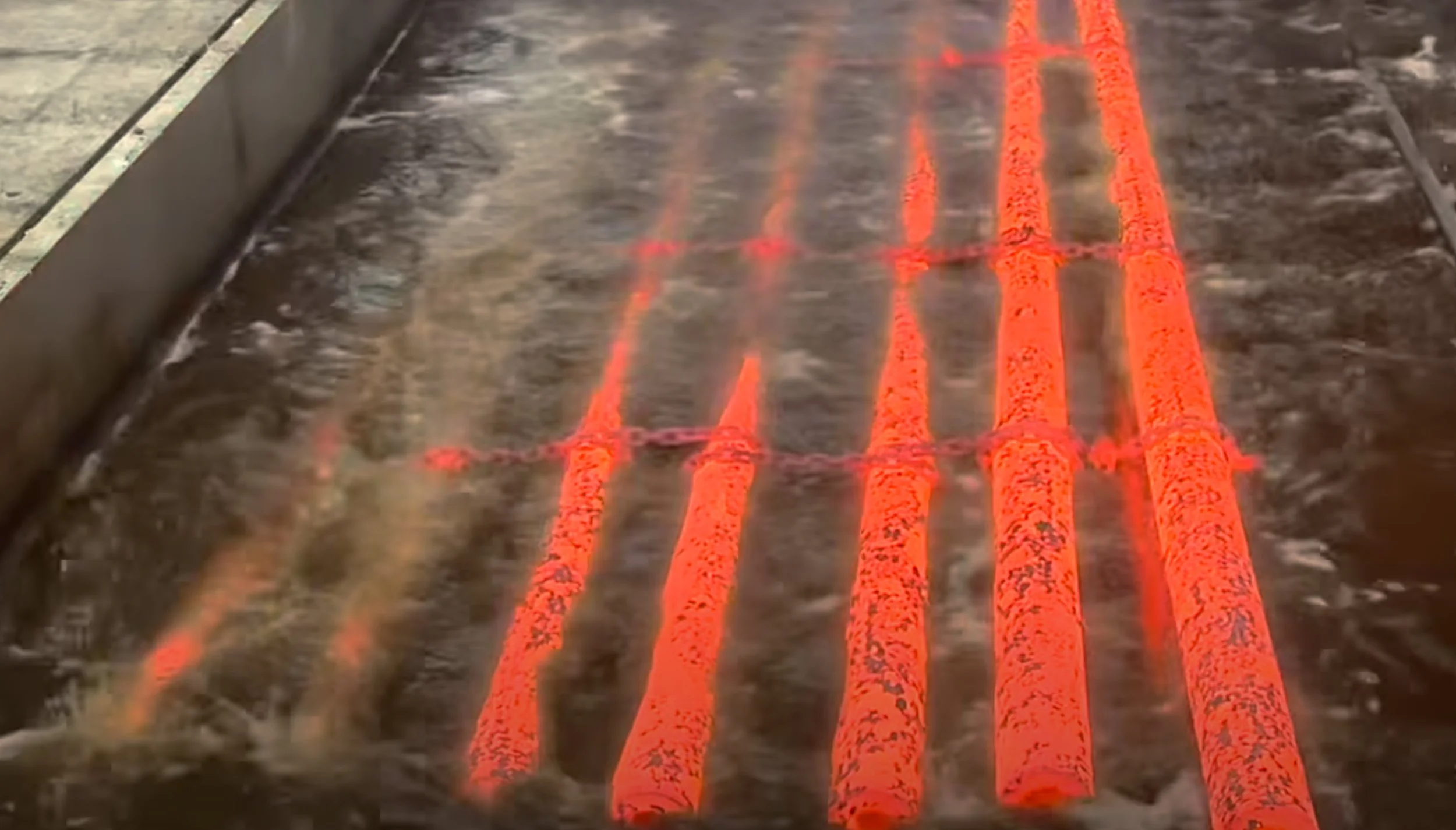

Quenching

Rapidly cooling, usually in liquid medium, to produce a desired crystalline structure.

Click Below for Video Samples

Age Hardening

A change in properties of certain metals and alloys that occurs at ambient or moderately elevated temperatures after hot working, cold working, or heat treating. The change in properties is often, but not always, du to a phase change (precipitation), but never involves a change in chemical composition of the metal or alloy.

Tempering

Heating uniformly to a predetermined temperature under the critical range and holding at that temperature for a designated period of time, then cooling in air. Used to produce one or more of the following end results:

Soften material for subsequent machining cold work

Improve ductility and relieve stress resulting from prior treatment or cold working

Produce the desired mechanical properties or structure in the 2nd step of a double treatment

Carburizing/Case Hardening

Can be used to increase hardness near the surface by diffusing carbon into the steel

Solution Annealing

Process used to change the mechanical properties of a material by dissolving any precipitates in the metal resulting in a single phase structure at the transformation temperature.

-

Heating uniformly to a temperature within or above the critical range and cooling at a controlled rate to a temperature under the critical range. This is used to produce a definite microstructure, usually for best machinability and/or to remove stresses and alter mechanical properties. When applied to nonferrous alloys, the term “annealing” without qualification implies full anneal. When applied to nonferrous alloys, annealing implies a heat treatment designed to soften a cold-worked structure by recrystallization or subsequent grain growth or to soften an age-hardened alloy by causing a nearly complete precipitation of the second phase in relatively coarse form. Any annealing process will usually reduce stress, but if the treatment is applied for the sole purpose of such relief, it should be designated stress relieving.

o Full anneal –

o Process anneal –

o Anneal for machining -

Stress Relieving

Thermal treatment to restore elastic properties and to minimize distortion on subsequent machining or hardening operations. This treatment is usually applied to a material that has been heat treated (quenched and tempered).

Additional Convenience Services

Specialty Heat Treat also offers additional convenience services include quality control services such as in-house testing, 3rd party testing and value added services such as straightening, cutting, shot blasting, and 3rd party lab testing.

Test Videos

Talk to Us

Interested in working together? Fill out some info and we will be in touch shortly, or use the info below to call or visit us. Either way, we can’t wait to hear from you!

Visit Our Shop

Specialty Heat Treat, Inc.

11307 W Little York Rd

Houston TX 77041

Call Us

Phone: (713) 937-3101